by Brad Strong | Aug 24, 2020 | Blog, CAD Diagnostics, CAD Performance, CAD Repair, CAD Translation, CAD Viewing, Training, What's New |

vThis article and video attempts to cover the majority of functionality you get with core TransMagic products, without going too long. In a 30-minute video, you can see a quick overview of what is possible with core TransMagic in one sitting, without having to go to multiple pages or videos. Many of our customers use TransMagic only for translation and basic repair, but you may have more in your tool box than you suspected. This video gives you a glimpse of what is already in your toolbox. Please note Tech Docs is covered in this video and is available only in TransMagic EXPERT. Other differences between core versions and functionality not covered in this...

by Brad Strong | Mar 30, 2020 | Blog, CAD Performance, CAD Systems, CAD Translation, CAD Viewing, Support, What's New |

JT is an unusual CAD file format which regularly causes some confusion amongst CAD users. This article will overview the JT format, explain what makes this format so unique, and show how to open a JT file. The JT Format JT is a CAD file format provided by Siemens PLM Software. JT stands for Jupiter Tessellation, which points to the fact that JT files are tessellated, or polygonal – also known as Viz-Rep, for ‘Visual Representation’; but what’s interesting about JT files is that they can also contain precise, CAD Brep geometry. So to be clear, JT files can contain both polygonal and CAD geometry. But, but in our experience, JT files only contain CAD Brep...

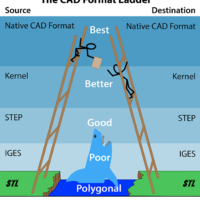

by Brad Strong | Mar 11, 2020 | Blog, CAD Performance, CAD Systems, CAD Translation, What's New |

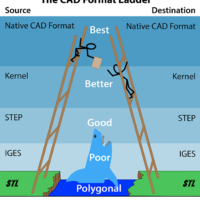

How do you choose the best CAD file format for any given situation? The CAD Format Ladder can help you optimize data exchange with your customer or supplier. At TransMagic we deal with thousands of CAD file translation and repair issues every year. These issues can be minimized by using this rule of thumb: “When sending out CAD data, or receiving CAD data, go as high up on the CAD format ladder as possible.” Your best results will come from requesting a CAD format that is as high-up on the format ladder as they can give you. You’ll also want to send data back to your customer in a format that is as high-up on the ladder as you can write. The higher you go on...

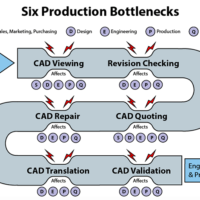

by Brad Strong | Mar 9, 2020 | Blog, CAD Comparison, CAD Diagnostics, CAD Performance, CAD Repair, CAD Systems, CAD Translation, CAD Validation, CAD Viewing, What's New |

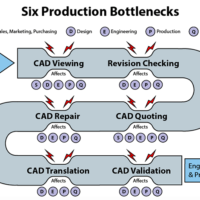

Normally, we think of production bottlenecks as occurring on the production floor; but there are upstream processes which can delay production as well as adversely impact manufacturing, quality assurance and scrap. CAD Viewing The inability for all project stakeholders to view and interact with CAD model data can become a production bottleneck, because 3D part and assembly models give the entire team a window into the project which could trigger necessary interventions early in the production process, before they become prohibitively expensive. CAD Viewers and 3D PDFs – This doesn’t mean all stakeholders need a full CAD seat, however; they might just...

by Brad Strong | Sep 11, 2019 | Blog, CAD Performance, CAD Systems, CAD Translation, CAD Viewing, What's New |

CATPart to STEP refers to translating or converting a native CATIA CAD model to the neutral STEP CAD format. This article will discuss some of the reasons you may want to do this, reasons you may not want to do this, and other formats you might want to consider translating to. This translation can also appear as CATIA to STEP, .CATPart to .STEP, CATProduct to STEP, .CATProduct to .STEP, .CATPart to .stp, and .CATProduct to .stp. The CATPart Format The CATPart format is created by CATIA. The other two 3D CAD formats which can be created by CATIA are CATProduct, and Model. CATPart and CATProduct extensions are used for CATIA V5 and V6; the difference between...

by Brad Strong | Sep 5, 2019 | Blog, CAD Performance, CAD Translation, What's New |

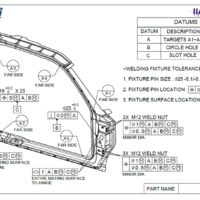

This article is in collaboration with Dimensional Control Systems, authored by Ben Reese, DCS Marketing, and Norm Crawford, Model Based Definition Specialist. Part 2 of the MBD Series with Norm Crawford – understanding what MBD is and the value of implementing MBD The second part of the DCS series of Model Based Definition (MBD) articles, Norm Crawford, an expert in MBD implementation, discusses MBD with us at DCS, and shares his experiences in both successes and failures in Model Based Definition. Read the Other Parts: Understanding Model Based Definition with an Expert in GD&T What is Model Based Definition MBD? Why Implement Model Based Definition? The...