by Brad Strong | Apr 6, 2020 | 3D Printing, Blog, CAD Comparison, CAD Diagnostics, CAD Repair, CAD Translation, CAD Validation, CAD Viewing, Polygonal Output, What's New |

By popular demand, this offer is extended to run until June 30, 2020. To help small businesses to be more productive during the COVID-19 crisis, TransMagic will be supplying 500 90-day complimentary licenses of our CAD viewing, healing and model validation software on a first come basis. This software will open all major 3D CAD formats and will be ideal for estimating/quoting, creating technical data packages, and compliance with Boeing D6-5991 specifications. These licenses will run 90 days. The exact configuration will be SUPERVIEW plus MagicHeal, for repairing geometry and creating water-tight solids, and MagicCheck, for high accuracy comparison between two...

by Brad Strong | Mar 9, 2020 | Blog, CAD Comparison, CAD Diagnostics, CAD Performance, CAD Repair, CAD Systems, CAD Translation, CAD Validation, CAD Viewing, What's New |

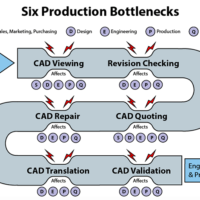

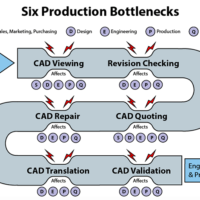

Normally, we think of production bottlenecks as occurring on the production floor; but there are upstream processes which can delay production as well as adversely impact manufacturing, quality assurance and scrap. CAD Viewing The inability for all project stakeholders to view and interact with CAD model data can become a production bottleneck, because 3D part and assembly models give the entire team a window into the project which could trigger necessary interventions early in the production process, before they become prohibitively expensive. CAD Viewers and 3D PDFs – This doesn’t mean all stakeholders need a full CAD seat, however; they might just...

by Brad Strong | Oct 2, 2019 | Blog, CAD Comparison, CAD Diagnostics, CAD Translation, CAD Validation, What's New |

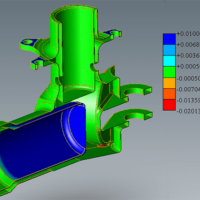

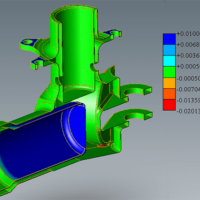

Avoid Million-Dollar Manufacturing Disasters Note: This blog post is a subset of a white paper entitled Avoiding Engineering Disasters which will be released soon, and contains more information as well as citations. We will post a link to the paper here soon. In engineering, something as simple as declaring the wrong unit of measure can create a disaster costing millions of dollars. John Pike, space policy director at the Federation of American Scientists, stated, “It is very difficult for me to imagine how such a fundamental, basic discrepancy could have remained in the system for so long,” regarding the English to Metric units mistake at NASA. Watch...

by Brad Strong | Aug 19, 2019 | Blog, CAD Comparison, CAD Performance, CAD Translation, CAD Viewing, What's New |

In 5 Ways to Improve Your Engineering Department we have compiled some of the best and highest-ranking advice for engineering managers and team members. Here’s the overview: Hire Smart, Humble Workers who Demonstrate the Ability to Get Things Done Keep Communication Flowing Between Design and Production Teams Encourage Open Debate, Make a Decision, Stop the Debate and Explain the Decision Examine Workflows and Define Processes Facilitate Continuous Improvement Hire for Smarts and Humility You want to hire the best possible person, so during the interview, don’t ask yes/no questions, but ask open ended questions that will give you some indication...

by Brad Strong | Jul 29, 2019 | Blog, CAD Comparison, CAD Repair, CAD Translation, CAD Validation, CAD Viewing, What's New |

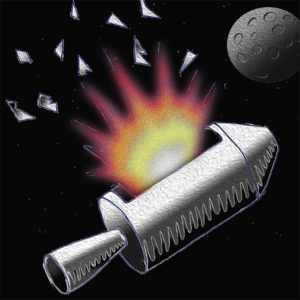

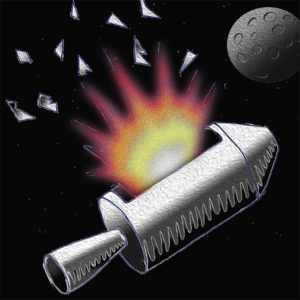

The purpose of How to Destroy a Spacecraft in 7 Easy Steps is to emphasize how easy it is to inadvertently make bad design and manufacturing decisions which can not only affect astronauts in the space program, but can extend to all sectors and endanger lives, products and companies. We honor the men and women who’ve given their lives to advance our space program. Many of us know the story of how the Apollo 13 spacecraft blew her oxygen tanks near the moon, nearly costing the lives of three astronauts, but through heroic acts and ingenuity, managed to limp home with all her crew intact. The incident nearly derailed the Apollo space program – but few of us know...