by Brad Strong | Jul 1, 2024 | Blog, CAD Translation, What's New |

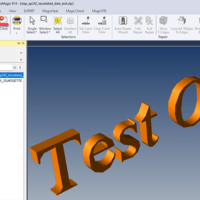

STEP AP242 allows for tessellated files to be saved to the STEP format. Tessellated files are polygonal files, or what are sometimes referred to as VisRep files. Most STEP files are true BRep CAD files, with ‘precise’ geometry (as opposed to ‘tesselated’ geometry. To open a tesselated STEP file with TransMagic, click on the TransMagic ‘star’ icon in the upper-left of the user interface, and choose Open QuickView. Then select the file you are interested in. At right you can see an example of a tessellated STEP file being opened with Open QuickView. In this case, the user wanted to convert the tesselated STEP file to a CAD...

by Brad Strong | Nov 28, 2023 | Blog, CAD Translation, What's New |

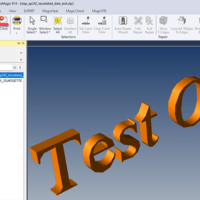

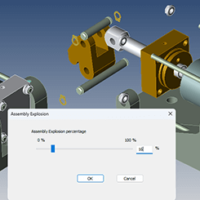

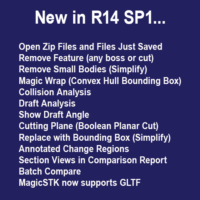

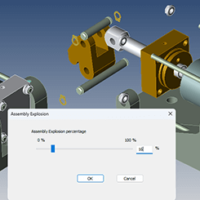

New CAD & Polygonal Format Versions CATIA V5 2023 R33 CATIA V6 2023 R33 ACIS 2023 NX 2212 Creo 9.0 JT 10.8 SOLIDWORKS 2023 AutoCAD 2022 Inventor 2024 Solid Edge 2024 Parasolid version 35 TMR R14 3D PDF up to 2023 27 New Time-Saving Features Described Below Get the PDF: What’s new in TransMagic R14 and R14 SP1 To get R14 SP1 + Installation Notes – Scroll to bottom of page New Features Available in All Core Products Assembly Explode (R14) Open any assembly and click Explode. Drag the slider for explode distance. Assembly Explode prompts you to flatten the assembly, and then drag a slider to determine how far to explode the assembly components....

by Brad Strong | Jun 5, 2023 | Blog, CAD Translation, What's New |

TransMagic R14 has new CAD format versions and a wealth of new features. Here’s the rundown. New Format Versions ACIS 2023 NX 2206 JT 10.8 SOLIDWORKS 2023 AutoCAD 2022 Inventor 2023 Solid Edge 2023 Parasolid version 35 3D PDF up to 2023 New Features in All Products Assembly Explode Export BOM (Bill of Materials) Export Dimensions, Markup and Annotations to 3D PDF Show Origin Create Center Point Create Centerline Show Surface Normal and Vertex Normal Convert T-Edges to Edges Industrial Part Colors New in MagicCheck: Compare PMI New EXPERT and MagicHeal: Defeaturing New Product: Magic STK – Bring your aerospace models into AGI’s System Tool Kit...

by Brad Strong | Oct 13, 2022 | Blog, CAD Translation, What's New |

New WebGL Capabilities The latest TransMagic build (12.31.400) has both a home button and an assembly tree display to improve viewing and CAD data access in a browser. The image at right was captured from Google Chrome, but any HTML5 browser will support the WebGL format. If you click the checkmark on any component, the part will no longer be visible in the assembly; checking the box causes the part to return. Clicking the ‘Home’ button makes the part return to a default zoom and position. Pressing and dragging with the left mouse button causes the part or assembly to rotate in 3D. Spinning the mouse wheel zooms the image. Pressing and dragging the...

by Brad Strong | Jul 19, 2022 | Blog, CAD Translation, What's New |

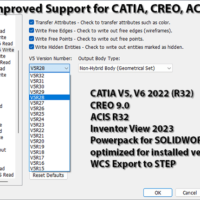

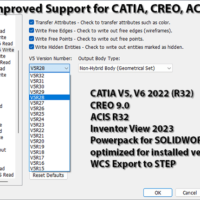

The latest build of TransMagic, 12.31.300, includes the ability to read and write to CATIA V5 2022 (R32) and CATIA V6 2022 (R32), Creo 9.0, and ACIS 2022 (R32). There is also support for Inventor View 2023, which leverages the ability to read Inventor 2023 files. Also new in the .300 build is the ability to export WCS entities in STEP, and COMMAND access to Include Body Edges with the [no]ineb option. IF you are running the Powerpack for Inventor add-on, there is an edit you will need to make to your registry in order to use the add-on work with Inventor 2022 or 2023, since Autodesk is now making all of their add-on “registry free”. Our development...

by Brad Strong | Feb 14, 2022 | Blog, CAD Translation, What's New |

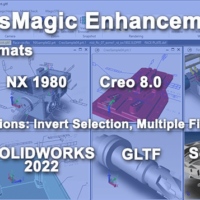

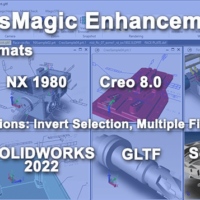

TransMagic has just released a new build – R12.31.200. For installation instructions, please see Installing TransMagic R12 SP2 and SP3 on our support portal. The latest round of TransMagic R12 enhancements include updated CAD format versions, new polygonal formats, and several other enhancements detailed below. Updated CAD Version Support NX 1980 (Continuous Release) SOLIDWORKS 2022 Solid Edge 2022 Creo 8.0 New 3D Formats FBX (new) – FBX stands for Filmbox. It allows storing of objects, materials and motion, making it ideal for game development applications. GLTF (new) – GLTF stands for Graphics Language Transmission...