by Brad Strong | Jul 6, 2016 | Blog, CAD Comparison, CAD Diagnostics, CAD Performance, CAD Repair, CAD Translation, CAD Viewing, Polygonal Output, What's New

‘Any sufficiently advanced technology is indistinguishable from magic’ – Arthur C. Clark The Magic Button The Magic Button is what you need at any given time; when you have a bad CAD model, the magic button is the Auto Repair button. When you have a CAD file you need to view, the magic button is the Open button. When you have a format you need to translate to, the magic button is the Save As button. And when you have two files you need to compare, the magic button is the Analyze button. It’s often a single button because that’s how TransMagic was developed, with simplicity in mind; sure, there are settings you can adjust if you...

by Brad Strong | Jun 20, 2016 | Blog, CAD Comparison, CAD Translation, CAD Viewing, Polygonal Output, What's New

TransMagic Release 12 brings with it a host of new enhancements to make you more productive. Check out the video below for a 3-minute overview, or scroll down to see a highlight of new features. New formats First of all, TransMagic Release 12 supports the latest version of all major CAD formats, including CATIA, Siemens NX, Creo, Solid Edge, Solidworks, Inventor, JT, Parasolid and more. New formats include 3DXML and WebGL; 3DXML is CATIA’s visualization format, and WebGL is a powerful, lightweight format with a .HTML extension which can be viewed in any HTML5 browser. WebGL also supports MBD (Model Based Definition), used by many aerospace and automotive...

by Brad Strong | Jun 13, 2016 | Blog, CAD Comparison, CAD Translation, What's New

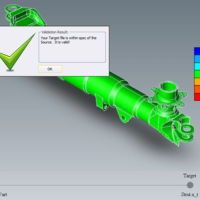

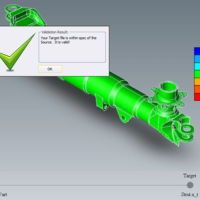

Validation Checking Part validation checking is similar to revision checking, but while revision checking assumes that there was a change (and seeks to find out exactly what changed between revisions), validation checking begins with the assumption that there was no significant change between two CAD models. Validation checking compares the authority part (provided by the customer) to the check part (usually generated as a result of translation by the supplier) to see if the geometry has changed beyond a given tolerance. Reasons for Validation Analysis For suppliers to perform their engineering and design tasks on the customer’s data, they often have to...

by Brad Strong | Mar 28, 2016 | CAD Comparison, CAD Translation

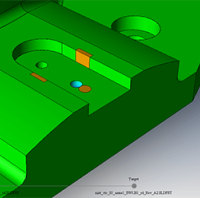

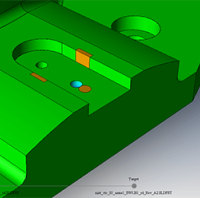

CAD Comparison is one of the most important and least understood areas in design and engineering today. Comparison software automatically evaluates the exact degree to which two models have the same geometry, provides a method to authenticate that the two models are the same for all practical purposes and determines how well a grouping of points fits to an existing 3D CAD model. TransMagic’s CAD Comparison solution is MagicCheck. A Bigger Problem than Perceived How does an estimator or designer quickly check that the revision the customer just sent actually only has the specified changes, and that there are no ‘surprise changes’ elsewhere in the file?...

by Brad Strong | Feb 23, 2016 | CAD Comparison, CAD Repair, CAD Translation, CAD Viewing

“TransMagic COMPLETE gives you the COMPLETE TransMagic suite for the ultimate in translation, repair, comparison and batch processing” TransMagic COMPLETE packs all the power of four products into one bundle; translate, repair, compare. You get the viewing, markup, interrogation and translation capability of Expert; the advanced repair and automatic surfacing tools of MagicHeal; MagicCheck’s ability to compare the geometry of two part revisions, validate geometry, or compare CMM points against CAD geometry; and the power to automatically translate and repair thousands of files at once via MagicBatch. Who’s A Good Fit For COMPLETE?...

by Brad Strong | Dec 15, 2015 | CAD Comparison, CAD Diagnostics, CAD Validation, What's New

“Protect your downstream manufacturing investment with Point-to-Part Comparison, Part-to-Part Comparison, and Part- to-Part Validation” MagicCheck CAD model comparison software quickly opens all major 3D CAD formats, including point data, to compare against the source CAD model and analyze accuracy. Produce validation, revision and inspection reports for quality control processes. Find errors early while they are still manageable. What’s A Good Fit For MagicCheck? Job Shops and service bureaus who need to verify customer revisions to ensure no unexpected changes are missed. Prototyping specialists who need to compare scanned points against the CAD...