by Brad Strong | Jul 12, 2016 | Blog, CAD Comparison, CAD Diagnostics, CAD Repair, CAD Translation, CAD Viewing, Polygonal Output, What's New |

As of April, the TransMagic Product Wizard was launched; this is a selection tool to help you figure out which TransMagic products are a good fit for you needs. The product wizard is available on the products page here. Simply select the radio buttons for the functionality you need, and the suggested core product and add-ons will automatically populate the area below. Want to try another set of options? Just check and uncheck radio buttons at will and the suggested configuration will change dynamically. Here’s a brief summary of the TransMagic Product Wizard View The View tools are included in all TransMagic core products. View All Major 3D Formats: At...

by Brad Strong | Jul 6, 2016 | Blog, CAD Comparison, CAD Diagnostics, CAD Performance, CAD Repair, CAD Translation, CAD Viewing, Polygonal Output, What's New

‘Any sufficiently advanced technology is indistinguishable from magic’ – Arthur C. Clark The Magic Button The Magic Button is what you need at any given time; when you have a bad CAD model, the magic button is the Auto Repair button. When you have a CAD file you need to view, the magic button is the Open button. When you have a format you need to translate to, the magic button is the Save As button. And when you have two files you need to compare, the magic button is the Analyze button. It’s often a single button because that’s how TransMagic was developed, with simplicity in mind; sure, there are settings you can adjust if you...

by Brad Strong | Jul 5, 2016 | Blog, CAD Performance, CAD Translation, What's New

Large CAD files are all too common for a large percentage of designers and engineers. We typically receive a few calls each week from customers and prospects who are wrestling with CAD parts and assemblies that are anywhere from 50MB to 1.5GB. Files this large can tax even the fastest machines and throw a wrench into your work schedule. What can you do about it? Make Sure You Have Enough RAM: The main requirement to work with large 3D CAD models and assemblies is available RAM in your setup. The recommended minimum RAM required to run TransMagic is 16MB. That should cover you for quite large parts or assemblies. For any CAD file except JT (JT is addressed...

by Brad Strong | Jun 27, 2016 | Blog, CAD Performance, CAD Repair, CAD Translation, CAD Viewing, What's New

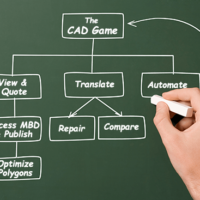

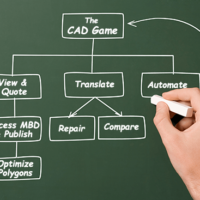

Many users of TransMagic purchase the software to simply translate from one format to another. This article points out 7 ways to improve your CAD game by digging deeper into TransMagic. View and Quote All many users need to do is open a customer CAD file and develop a quote for developing molds, tooling, machining, or some other service. Often, companies are using full CAD seats for viewing and quoting. TransMagic opens more formats and has a simpler, faster interface for viewing and quoting. Every core TransMagic product will open up 3D geometry from any major CAD system. Quickly add dimensions and notes, assign materials and generate mass properties for...

by Brad Strong | Jun 20, 2016 | Blog, CAD Comparison, CAD Translation, CAD Viewing, Polygonal Output, What's New

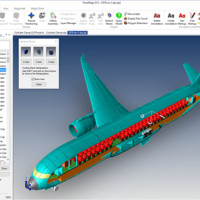

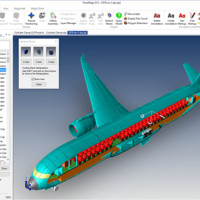

TransMagic Release 12 brings with it a host of new enhancements to make you more productive. Check out the video below for a 3-minute overview, or scroll down to see a highlight of new features. New formats First of all, TransMagic Release 12 supports the latest version of all major CAD formats, including CATIA, Siemens NX, Creo, Solid Edge, Solidworks, Inventor, JT, Parasolid and more. New formats include 3DXML and WebGL; 3DXML is CATIA’s visualization format, and WebGL is a powerful, lightweight format with a .HTML extension which can be viewed in any HTML5 browser. WebGL also supports MBD (Model Based Definition), used by many aerospace and automotive...

by Brad Strong | Jun 13, 2016 | Blog, CAD Comparison, CAD Translation, What's New

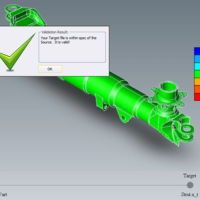

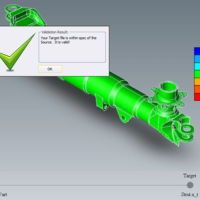

Validation Checking Part validation checking is similar to revision checking, but while revision checking assumes that there was a change (and seeks to find out exactly what changed between revisions), validation checking begins with the assumption that there was no significant change between two CAD models. Validation checking compares the authority part (provided by the customer) to the check part (usually generated as a result of translation by the supplier) to see if the geometry has changed beyond a given tolerance. Reasons for Validation Analysis For suppliers to perform their engineering and design tasks on the customer’s data, they often have to...