by Brad Strong | Jun 27, 2016 | Blog, CAD Performance, CAD Repair, CAD Translation, CAD Viewing, What's New

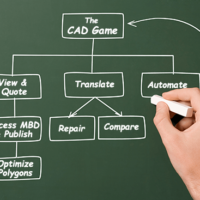

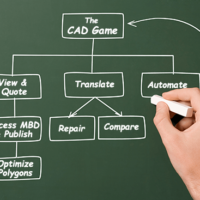

Many users of TransMagic purchase the software to simply translate from one format to another. This article points out 7 ways to improve your CAD game by digging deeper into TransMagic. View and Quote All many users need to do is open a customer CAD file and develop a quote for developing molds, tooling, machining, or some other service. Often, companies are using full CAD seats for viewing and quoting. TransMagic opens more formats and has a simpler, faster interface for viewing and quoting. Every core TransMagic product will open up 3D geometry from any major CAD system. Quickly add dimensions and notes, assign materials and generate mass properties for...

by Brad Strong | Jun 6, 2016 | Blog, CAD Repair, What's New

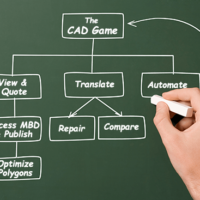

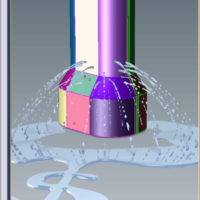

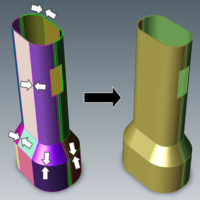

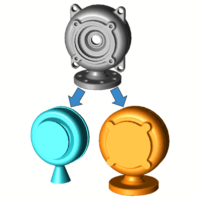

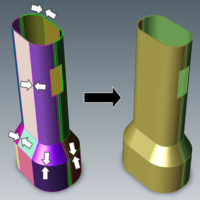

TransMagic’s MagicHeal has the ability to take a CAD model such as this discharge casing (courtesy of Nayla Miana Luiz, as seen on GrabCAD) and perform ‘CAD Inner and Outer Volume Separation’, or split the geometry out into inside and outside volumes (see figure at right). Generating inside and outside volumes could be useful for generating precise estimates of surface finishes or coatings, or in mold development (where each volume becomes a core body). In the process of generating these solid bodies we remove various features, so this is also a tool for defeaturing a model. There are various reasons you might want to remove features from a model,...

by Brad Strong | Jun 1, 2016 | Blog, CAD Performance, CAD Repair, CAD Translation, What's New

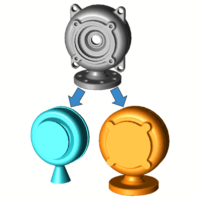

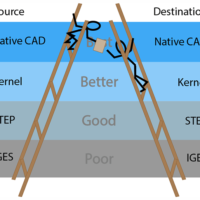

In The CAD Format Ladder Part 1 we looked at using the CAD Format Ladder to attain the end-goal for translation: high-quality geometry, a water-tight solid if possible, and PMI data if it is included. You can access The CAD Format Ladder Part 1 here. In The CAD Format Ladder Part 2, we’ll look at some specific scenarios. Native, Kernel, and Neutral Formats For clarity, we will define “Native Formats” as the format that is written by default by any given CAD system; for example, CATIA uses .CATPart and .CATProduct, and SOLIDWORKS uses .sldprt and .sldasm as their native formats. The native format is always going to contain more metadata. In addition...

by Brad Strong | May 19, 2016 | Blog, CAD Diagnostics, CAD Repair, CAD Translation, What's New

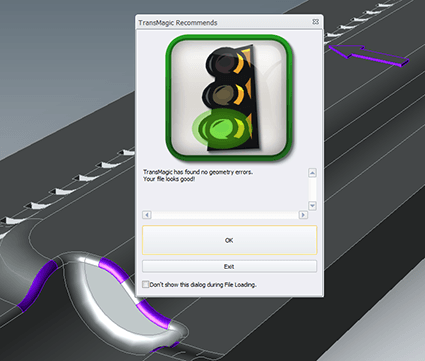

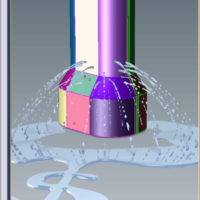

To see how fast you can repair CAD geometry, and how easily models with missing geometry can be covered with new faces using TransMagic’s MagicHeal, check out this step-by-step walkthough. The process of covering holes and stitching it all together into a watertight solid is quick and easy. Here are the steps (video example at end of this article): STEP 1 – Auto Repair Wizard Start by running the TransMagic Auto Repair Wizard, a tool which automatically validates geometry and repair functions (see figure 1). This automatic CAD repair tool runs Lite Repair which stitches surfaces together as long as the surfaces meet within a specified...

by Brad Strong | May 10, 2016 | Blog, CAD Repair, CAD Translation, CAD Viewing, What's New

‘Six reasons watertight models matter’ makes the case that whenever possible, surface models should be converted to solid models. What is a ‘watertight’ solid model? Imagine your CAD model was made of ice, and we wrapped it in plastic wrap, the plastic wrap representing the surfaces on your part. If we now melted the ice, would the water be able to leak out? If so, you have a ‘leaky’ model, meaning the model is not watertight. What causes model leakiness? If any faces on the part are missing, or if you have any neighboring surfaces that are unstitched, you’ve got a leak. Visualizing a cube, if any of the six surfaces are missing, or if any two...

by Brad Strong | May 3, 2016 | 3D Printing, Blog, CAD Repair, CAD Translation, Polygonal Output, What's New

Eleven Techniques to Optimize 3D Printing CAD Files 3D printing and additive manufacturing processes are increasingly being used in to achieve quick turnaround on prototypes and to generate complex models cost effectively in low volume. Preparation of the geometry is the key to getting optimum results with 3D printing. The following techniques can shave hours off of the process of 3D printing CAD files. 1. Watertight Models Designs used for 3D printing need to be watertight solid models. 3D printers pre-process models into very thin horizontal slices of the part. Watertight geometry is necessary for the preprocessing step to avoid errors. Often,...