by Brad Strong | Nov 27, 2018 | 3D Printing, Blog, CAD Performance, What's New |

OMAX, a manufacturer of abrasive water jets for machine shops, fabricators and manufacturing companies, discusses how they use TransMagic to solve 3D CAD data problems. Abrasive waterjet cutting is impressive. These sophisticated machines can cut a large range of materials with ease and accuracy, from extremely hard metals to volatile substances, using only water and an abrasive. With the wide range of materials they can cut, industrial waterjets are often used with complex geometries. This is a story of how OMAX and TransMagic work together to solve complex 3D CAD data problems. When Problems Exist in the 3D Data Model OMAX’s CNC software is Intelli-MAX. It...

by Brad Strong | Sep 17, 2018 | Blog, CAD Performance, CAD Translation, Training, What's New |

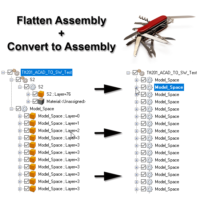

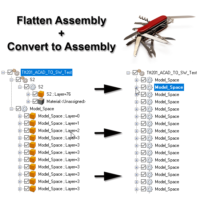

Some of the tools in TransMagic can be lifesavers when you need them, and they often can work together like a Swiss army knife; two such tools are Flatten Assembly and Convert to Assembly. It is important to note that usually our customers either use one or the other of these tools to solve disparate problems. An application came up recently that allows us to use both of these tools together – here’s the workflow to go from an unusable, multibody DWG to a valid assembly file: DWG File Structure Before FlatteningFiles generated in AutoCAD Modelspace were imported into SOLIDWORKS, but the parts in the assembly weren’t showing up. When the DWG...

by Brad Strong | Jul 16, 2018 | Blog, CAD Performance, CAD Repair, CAD Translation, CAD Viewing, Polygonal Output, What's New |

Many people don’t realize that when they buy TransMagic PRO or EXPERT, they automatically gain access to the PowerPack for SOLIDWORKS. TransMagic’s PowerPack for SOLIDWORKS provides thirteen more formats for SOLIDWORKS users, including CAD and polygonal formats, the latest versions of those formats, and built-in repair tools, all from inside the SOLIDWORKS interface! With additional formats and versions, you have the ability to serve a wider range of customers and you have more options in those instances where there is a problem reading or writing a particular format. Not only that, but you have access to different versions of the same translator;...

by Brad Strong | Jan 15, 2018 | Blog, CAD Diagnostics, CAD Performance, CAD Repair, CAD Translation, Polygonal Output, What's New |

We’ve covered a lot of ground in the past two years. Here are the top twelve TransMagic articles from 2016/2017. Actually, it’s hard to measure what the top blogs were in any given year; do you count the number of views? In that case, older articles have a definite edge. In this case we looked at the posts getting the most views during the last 30 days. Here they are: #1 SOLIDWORKS Performance! Optimizing SOLIDWORKS Performance: SOLIDWORKS is still the clear leader in terms of existing MCAD seats, and is always a popular subject. This article goes over several hardware and software suggestions for significantly improving SOLIDWORKS performance....

by Brad Strong | Nov 13, 2017 | 3D Printing, Blog, CAD Diagnostics, CAD Performance, CAD Translation, What's New |

This article will demonstrate how materials are applied to models in TransMagic R12, and how parts and assemblies can then be interrogated for Mass Properties. Mass properties are particularly useful if you are generating quotes or estimates, and need to know the weight or volume of materials for the part or complete assembly. Another common use for mass properties is to get the volume calculation for estimating 3D printing print times and material costs. The Mass Properties dialog box also provides moments of inertia and allows you to create three planes that intersect at the centroid. Applying Materials Parts should already have a default material assigned;...

by Brad Strong | Jul 24, 2017 | Blog, CAD Diagnostics, CAD Performance, CAD Repair, CAD Translation, What's New |

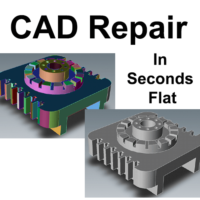

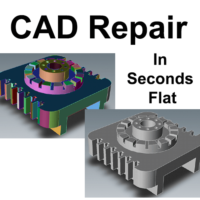

All core TransMagic products come with the Auto Repair Wizard and Lite Repair, giving you CAD repair in seconds flat. By default, every model that is opened is evaluated by the Auto Repair Wizard (ARW) to see if it is a watertight solid, and if there are any underlying issues. In the before-and-after image at right, the ‘before’ image has different default colors for each face or surface; this is an indication that you are dealing with an group of surfaces rather than a watertight solid model. In the ‘after’ image, the color of the model is uniform, indicating that the model is a cohesive solid. Red, Yellow or Green Light? Based on what...