When checking customer revisions, if you miss a change, there is the potential to order wrong parts and even manufacture wrong parts.

I sometimes ask TransMagic users how often their customers make changes that are undocumented; one said “oh, about 85% of the time”; another said “7 out of 10 times”. Apparently it is not that unusual for the customer to fail to communicate all the changes made at each revision.

If estimators of the manufacturing world miss a single customer change they run the risk of:

- Misquoting the part, thereby potentially charging too little for the tooling they create

- Creating the wrong tooling, thereby wasting time and material

- Endangering their customer relationships (even if the hidden change was the fault of the customer)

The burden is on the estimator, or another in-house engineer or designer, to catch all customer changes.

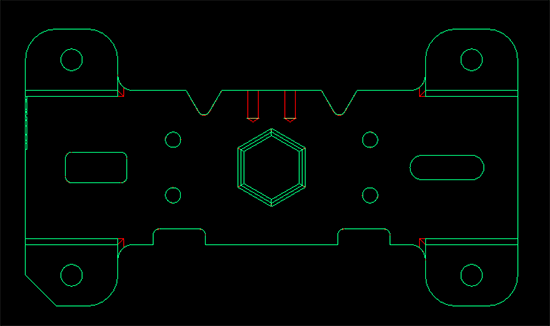

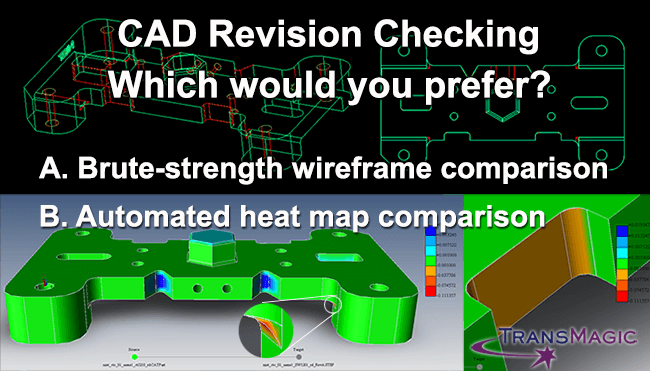

The Red-Green Wireframe Brute-Force Method

How do estimators, designers and engineers currently check customer revisions? One technique we hear a lot about involves bringing the original model and the revised model into the same CAD session, coloring one red and one green, switching to wireframe display mode, and engaging brute-force visual inspection to look for changes.

This puts a large burden on the already-taxed eyes of the technical staff, and the risk is always there that they will miss something. Often, changes are small as designs are tweaked and fits are adjusted; thousandths of an inch variation are hard to see in a wireframe model.

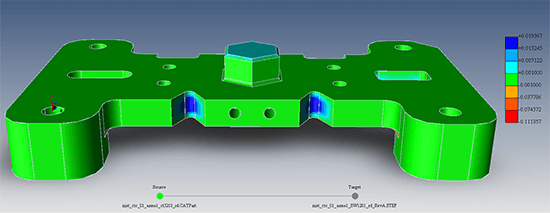

The Automatic Heat Map Method

When you compare visual discrepancy checking against automated heat-map comparison, it sounds barbaric. Small changes are difficult to see, and if the model is sufficiently complex, it will look like a wireframe jungle anyway.

MagicCheck allows you to compare two models in the context of the assembly or separately, and set your own tolerance. You’ll know in seconds where and how much the revision changed, and if there is a change outside the tolerance of .001 in. (or whatever tolerance you set), you’ll see it plain and clear. Need a report? Just a single button click, and a part-to-part analysis report will be produced and saved to PDF.

The video below demonstrates a few examples of MagicCheck revision analysis in 2 minutes.