All core TransMagic products allow you to calculate mass properties (weight, volume, centriod), surface area, create a bounding box, measure and add dimensions – but have you ever needed to calculate the length of straight or curved edges? You might need to know edge length in order to estimate a particular machining operation, for example breaking edges. Getting that value is not intuitive, so we thought we’d show you how here. It’s basically a two-step process:

All core TransMagic products allow you to calculate mass properties (weight, volume, centriod), surface area, create a bounding box, measure and add dimensions – but have you ever needed to calculate the length of straight or curved edges? You might need to know edge length in order to estimate a particular machining operation, for example breaking edges. Getting that value is not intuitive, so we thought we’d show you how here. It’s basically a two-step process:

Select Edges to Measure

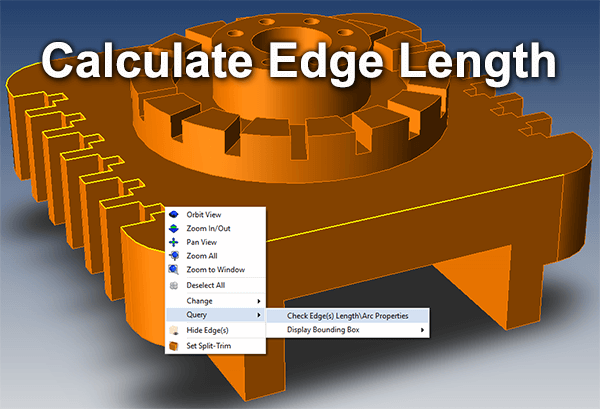

Select the edges you want to get the length of. As you can see in this first screenshot at right, we have a solid model that has had several edges selected (highlighted in yellow). In this case we’re just selecting half of the edges since the part is symmetrical; selecting half and then doubling the result will give us the full distance around the part. To select edges, you can just select the edges with the Single Select tool, keeping the Ctrl key held down until all edges have been selected. Note: It is sometimes easier to select edges if you get into Edge selection mode; to do so, select the ‘down arrow’ next to the white selection arrow on the left side toolbar. Choose ‘Edge’ mode. Now you will be forced to select only edges.

Right Click, Calculate Edge Length

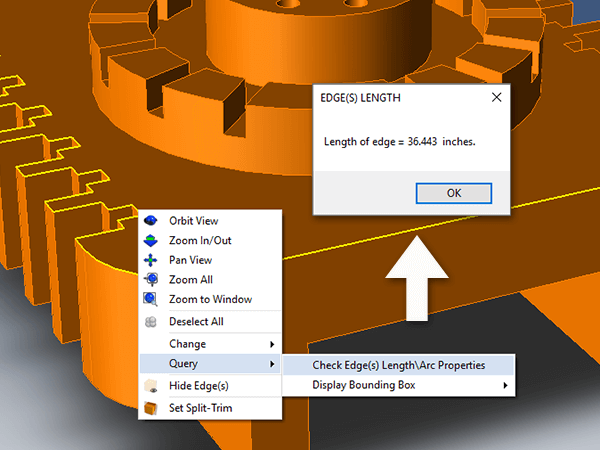

Once all edges have been selected – then right click in the screen area and click on Query > Calculate Edge Length – the total cumulative length of all selected edges should appear in the message box (see screenshot at right).

Now that your operation is complete, don’t forget to change the Single Select setting back to ‘Dynamic’ or ‘Body’ when you are done with your calculation, otherwise you’ll be limited to selecting edges!

Note: Units in this case are inches, but units can be changed in Settings > General > General Info to millimeters, etc.

We hope this post has been helpful to you, and welcome your questions or comments at social@transmagic.com.