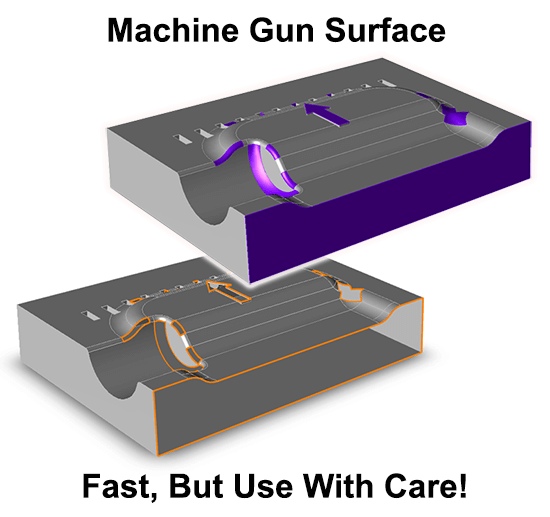

Machine Gun Surface replaces missing faces and surfaces until the CAD model is watertight. This a feature that customers have asked for over the years, and now it is finally in TransMagic – and as the graphic says, it’s fast, but using it correctly requires some forethought.

Machine Gun Surface replaces missing faces and surfaces until the CAD model is watertight. This a feature that customers have asked for over the years, and now it is finally in TransMagic – and as the graphic says, it’s fast, but using it correctly requires some forethought.

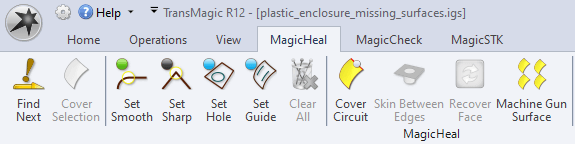

Machine Gun Surface is an automatic version of the Find Next & Cover feature found in Advanced Repair, part of the MagicHeal add-on. The benefit of Machine Gun Surface is that, once you hit the button, it will cycle through all openings in a model until it is done, meaning that dozens or even hundreds of surfaces can be added in just a few minutes. But, we highly recommend you don’t just click Machine Gun Surface – first, think about the holes you want to cover; is the neighboring geometry planar, or curved? Machine Gun Surface cannot add Set Smooth attributes (used for holes where you want the new surface to be tangent to the hole edges). Therefore, if you do not add Set Smooth attributes to the edges you want to surface, Machine Gun Surface will assume you want Set Sharp attributes and will proceed to add surfaces accordingly.

Things to keep in mind when using Machine Gun Surface

- New Surfaces are Based on Open Circuits: Machine Gun Surface replaces missing surfaces by detecting existing surrounding geometry, otherwise known as ‘circuits’; the new surfaces are purple so it is clear that they are derived. This is important because if two or more neighboring surfaces are missing, Magic Surface has no way to calculate the ‘edge’ that was between them, thus that information is lost. So while Magic Surface is a great tool, it cannot recreate the missing original geometry; it simply covers openings with Smooth or Sharp edge attribute settings applied to edges. If you fail to apply attributes to open circuit edges, Set Sharp attributes will be assumed.

Start by Assigning Attributes to All Open Circuits: Use the Find Next tool to find the open circuits, then, one at a time, select an edge on an open circuit and assign ‘Set Smooth’ or ‘Set Sharp’ attributes to the openings (see screenshot at right). Again, if you do not assign attributes to an edge, ‘Set Sharp’ attributes will be assumed. So if you have a model with ten open circuits which need to be covered, and you want Smooth attributes to be used on three of the holes, go ahead and set the attributes on those three holes before you run Machine Gun Surface.

Start by Assigning Attributes to All Open Circuits: Use the Find Next tool to find the open circuits, then, one at a time, select an edge on an open circuit and assign ‘Set Smooth’ or ‘Set Sharp’ attributes to the openings (see screenshot at right). Again, if you do not assign attributes to an edge, ‘Set Sharp’ attributes will be assumed. So if you have a model with ten open circuits which need to be covered, and you want Smooth attributes to be used on three of the holes, go ahead and set the attributes on those three holes before you run Machine Gun Surface. - Underlying Repair Issues Must Be Addressed: Sometimes Magic Surface is unable to apply a surface to an open circuit because there are underlying issues, such as self-intersections or duplicate vertices. To address more serious issues with geometry, select the surfaces in question and run Full Repair. Then try Magic Surface again.

- Newly Created Surfaces can be Deleted: If for any reason you are not satisfied with a newly applied surface, simply select it with the Single Select tool and delete it by pressing the Delete key on your keyboard.

- Some Holes are not meant to be covered: In the image above, the arrow boss is missing sidewalls, which is repaired with another technique. If you try to run Machine Gun Surface on it, it will just surface over the arrow hole in the top of the part; not the solution we want. So a good rule of thumb is to run Machine Gun Surface when the only remaining open circuits are those you want covered, and they all have had either Smooth or Sharp edge attributes assigned.