Automation Customer Stories

Omax

“Our Intelli-MAX software is comprehensive, but it requires valid geometry. With TransMagic, I can confirm the 3D model is valid and I can fix it quickly and easily if needed.”

OMAX has been a pioneer in cutting materials with water. In 1993, they introduced the first PC controller for abrasive waterjet machining and the JetMachining® Center specifically designed for machine shops. They are still leading the way with new patents, models, and recognition. For example, they recently became ISO 9001 certified and received the Seattle Business Magazine’s Manufacturer of the Year Award.

OMAX has been a pioneer in cutting materials with water. In 1993, they introduced the first PC controller for abrasive waterjet machining and the JetMachining® Center specifically designed for machine shops. They are still leading the way with new patents, models, and recognition. For example, they recently became ISO 9001 certified and received the Seattle Business Magazine’s Manufacturer of the Year Award.

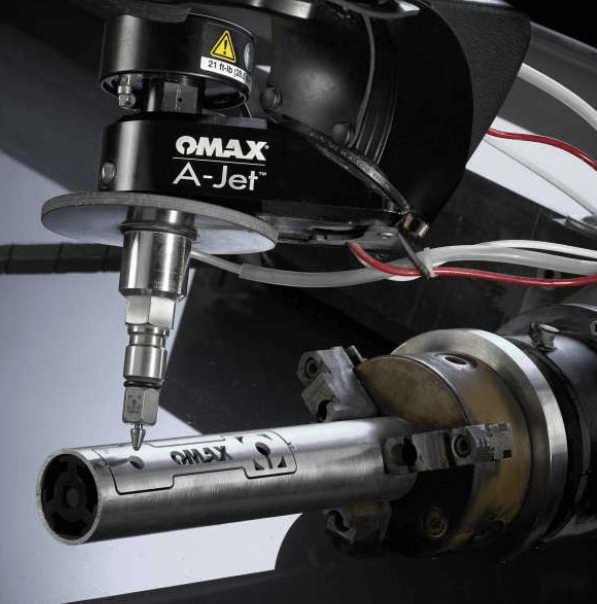

Serving diverse industries including aerospace, automotive, transportation, energy, agriculture and architecture, an OMAX waterjet is an unstoppable cutting machine. The OMAX waterjet shoots a high-pressure stream of water and abrasive at over Mach 1 to cut almost any material. “OMAX is a machine tool provider whose customers are typically machine shops, repair shops, fabricators, manufacturers, and the military. Our waterjets are used in a wide variety of businesses and for cutting some very exotic materials,” said Mark Rodgers, OMAX Software Support Specialist.

OMAX is a hardware and software company,” said Rogers. “The machine is just one side of our solution, our Intelli-Max software that controls the cutting process is just as important.” OMAX waterjets are Computer Numerically Controlled (CNC). CNC programming for cutting flat material is straightforward; the complexity comes with 3D. The more complex the 3D model – created with a mechanical CAD program like CATIA, Creo, Inventor, NX, Pro/E, SOLIDWORKS, and others – the more difficult the CNC programming gets. As the OMAX Software Support Specialist, Rogers has been involved with many complex and unique projects that have been performed with the OMAX waterjet.

When Problems Exist in the 3D Data Model

“TransMagic is my ‘go-to tool’ when I receive geometry that has problems.”

OMAX’s CNC software is Intelli-MAX. It is very powerful, yet easy-to-use. For 3D files Intelli-MAX gets its data from Intelli-CAM. A valid solid model is required for Intelli-CAM to function properly. Sometimes, a customer will have a problem with their own 3D geometry created from any number of 3D CAD programs. For example, a common problem is a non-manifold condition.

TransMagic can detect even the slightest problem with 3D geometry and alert the user. For many cases, TransMagic can perform the repair with the press of a button. For more complex situations, the software will guide the user through the repair process. In both cases, neither a CAD license or having CAD experience is required. After verifying and possibly repairing the 3D geometry, it is ready for transfer to the OMAX Intelli-MAX software using the STEP file format. TransMagic can translate over 40 different formats, so OMAX waterjet customers using TransMagic can accept basically any CAD data format as input, verify the model integrity and fix it if needed (without using a CAD system), and lastly generate the model in the STEP format. This saves time and money while streamlining the process.

“TransMagic is my ‘go-to tool’ when I receive geometry that has problems.” Says Mark. “Customers buy our waterjet cutter to do amazing things. Without a valid 3D model, nothing can happen.” Rogers described the challenges that come with any complex project. “The thing all of these complex cutting operations have in common is 3D geometry. Our Intelli-MAX software is comprehensive, but it requires valid geometry. With TransMagic, I can confirm the 3D model is valid and I can fix it quickly and easily if needed.”

Customer Example: Cutting Carbon Fiber Turbine Blades

An OMAX customer needed to cut carbon fiber turbine blades. Waterjet cutting is an excellent choice for cutting carbon fiber. “The geometry was a mess, it took me three months to fix it before we could bring it into Intelli-MAX,” said Rogers. That was before TransMagic – that same project could now be done in days. “Having a valid 3D model as input to Intelli-MAX is critical. Translating, diagnosing and fixing problems can become a bottleneck for our customers – TransMagic addresses all of these quickly and with the highest quality” Rogers said.

Solving Problems

“Now when facing a tough problem from a customer,” Rogers confidentially says “with TransMagic, we can do that!’”

“There are two faces of my job. Sometimes we will perform jobs for our customers; these tend to be the complex and difficult ones. Other times, I am brought in more as a consultant to one of our customers. Now when facing a tough problem from a customer,” Rogers confidentially says “with TransMagic, we can do that!’”

Further information at www.OMAX.com.

Altron Automation

Altron Automation builds automation tooling for assembly processes, material handling and product testing.

Before TransMagic

The rough cost for quoting 50-70 files per year was $70 each for translation to STEP. More data is coming in every year, so translation costs alone are expected to go up to $5250-$7000 per year. Costs are increased by poor data and multiple revisions for each project. These estimates do not include Engineering’s time to translate and repair the resulting STEP files; on average this cost is 1-2 hours per file to make the file workable, so the cost runs up to another $3500-$7000 per year, for a total cost of $8750-$14000 per year. Costs in terms of delays are complicated by FTP; sending the data to the vendor by FTP typically costs 1 day before the file is acknowledged as received, and receiving the data back by FTP generally takes another day. Opening the file and making the file workable (including fixing any errors) can take another half day. This totals 2-3 days of time cost per project.

After TransMagic

Outside of the cost of TransMagic, with no file transfer to translation service bureaus, costs are between 30 minutes and 2 hours per file to make the file workabout (at $70/hr rate) – which greatly improves project response. This totals between $875-$7000 per year. Implementing TransMagic has dramatically reduced translation costs.

Other Benefits

Sales doesn’t need to have engineering involved to manipulate data, leading to quicker turn around time on quotes and proposals. It’s quicker to open files; TransMagic allows direct viewing of the files which previously took days to get.

Further information at www.AltronAutomation.com.