Executive Summary

An high-level overview of how TransMagic can accelerate your engineering and manufacturing processes.

Reduce Cost

Reduce Cost

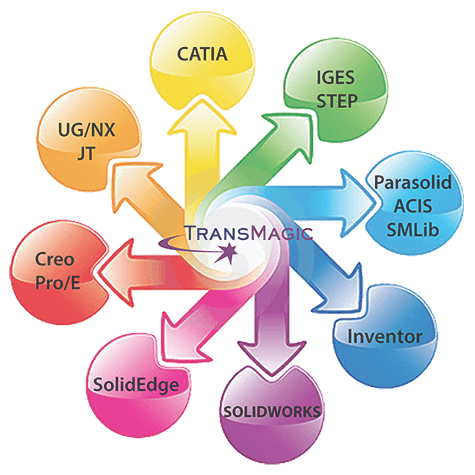

- Eliminate multiple CAD software needs – A seat of TransMagic can often substitute for the CAD software you are using to read, view and write to diverse CAD formats, saving on training, licensing and maintenance costs.

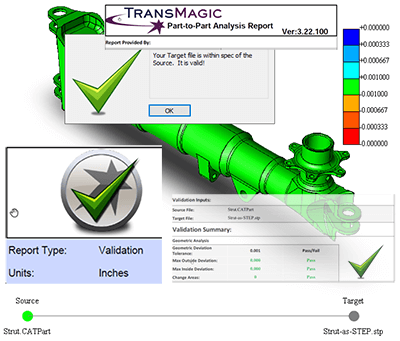

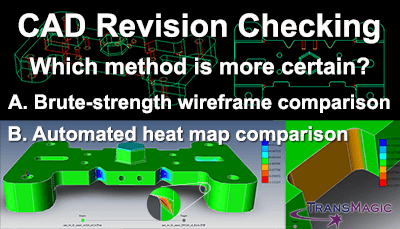

- Prevent Costly Mistakes – Getting the best CAD data possible, and knowing exactly what has changed in a customer revision can help you avoid model repairs, model re-creation and downstream manufacturing errors.

Restore Design Intent

Restore Design Intent

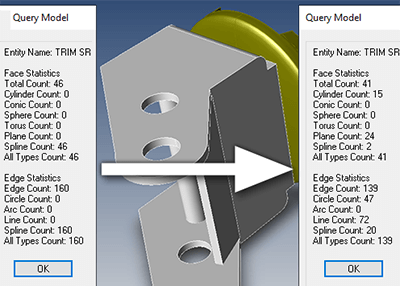

- Recognize true analytic 3D geometry shapes – Lite Repair converts poor quality spline data to true cylinders, planes and edges, which are more easily recognized by downstream CAD and machining applications.

- Solve difficult geometric issues automatically – Full Repair can tweak geometry to restore original intent, closing gaps and re-creating analytics in mere seconds and with a single button click.

Eliminate Waste

Eliminate Waste

- Detect unexpected design changes and validate quality – MagicCheck spots all changes between revisions, whether the customer notified you or not, and validates against the original customer file to the precision you specify.

- Eliminate duplication of design effort – High-quality translation filters down the number of problematic models, and automatic repair tools free designers and engineers up from tedious model repair and rebuilding tasks so they can get more quotes and designs out the door.

Reduce Schedule Time-to-Launch

Reduce Schedule Time-to-Launch

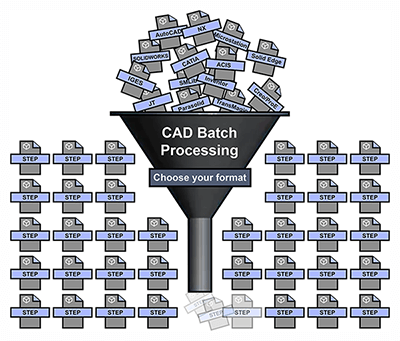

- Streamline processes to eliminate time delays – MagicBatch allows you to translate and repair hundreds or thousands of files at one time. COMMAND automatically translates and repairs files with no user intervention necessary; just have team members put their files into a network folder and translations to several multi-CAD formats proceeds instantly.

- Facilitate maintenance, repair and overhaul (MRO) operations – Document MRO operations with native and neutral CAD formats, write to 3D PDF as a format everyone in the organization can read, and take advantage of Tech Docs, which combines the 3D PDF with attached CAD formats and notes of your choice.

Read more about automating translation and repair of CAD files.

Democratize Engineering Product Data

Democratize Engineering Product Data

- Access product designs for analysis, documentation and manufacturing – Read every major 3D CAD format in the world, write to STL (for FEA), 3D PDF (for documentation) and native, kernel and neutral formats (for manufacturing).

- Collaborate easily with customers, vendors and departments – 3D PDF and WebGL are lightweight, effective formats for communicating internally or externally. Read and write CAD native and neutral formats as well as polygonal formats and tune over 200 settings to give you and your customers the ideal solution in today’s multi-CAD world.

Accelerate Engineering Production

Accelerate Engineering Production

- Leverage 3D Digital Design Data for critical engineering functions – Whether you need to view or measure true CAD data, quote a customer inquiry, integrate multi-CAD data into your design, or collaborate with internal or external customers, TransMagic has you covered.

- Avoid work-stoppage from data errors – Missed revisions due to poor customer communications can lead to manufacturing the wrong part; MagicCheck helps you verify revision changes and validate model integrity to the tolerance you select.

- Transform tedious time-consuming tasks – From instant, one-button repairs to batch and even automated translations and data extraction for analysis, get the best data possible, as quickly as possible.

Increase Product Data Quality

Increase Product Data Quality

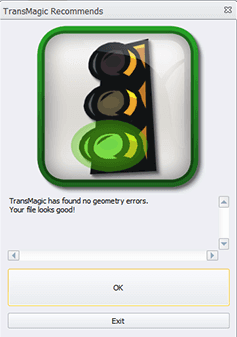

- Check digital model quality for use in any CAD/CAM/CAE application – Use TransMagic’s Lite Repair as a diagnostic tool to check model quality; green light? The model is good! Red or yellow light? There’s a problem with the model which you can either repair on the spot, or contact the customer for a better-quality model, or a different CAD format.

- Mitigate design data errors with over 1.8 million lines of heuristic code – Lite Repair, Full Repair and MagicHeal represent a three-stage approach to CAD data errors which have been developed through almost two decades of repairing customer models and assemblies; the majority of these can be resolved in mere seconds.

Request a 7-Day TransMagic Evaluation

Evaluate TransMagic for 7 days to see how it works with your parts!

Subscribe to Newsletter

Never miss a newsletter or a special offer from TransMagic!

Testimonials

ProNor AS

After many problems with files translation we tried TransMagic and successfully converted a very large surface model of a Norwegian oil rig to a solid model that we can now open in SolidWorks. TransMagic has done a tremendous job for us.

– J. I., ProNor AS

– J. I., ProNor AS

BRC Rubber and Plastics

TransMagic lets me share 3D models with our 5 locations that do not have CAD software. This has improved communication and saved time getting approvals, preparing job quotes and solving manufacturing issues. This capability has eliminated many communication problems between our design and build leaders.

– P. P., BRC Rubber and Plastics

– P. P., BRC Rubber and Plastics

J. O.

TransMagic is a great value because we need to open CAD files for quoting purposes…the cost is easily justified.

– J. O.

– J. O.

What’s New