CAD Model Validation for Aerospace

How can you be certain that the part you translated to STEP for your analysis is within a reasonable tolerance to the original part dimensions?

How can you be certain that the part you translated to STEP for your analysis is within a reasonable tolerance to the original part dimensions?

This is a problem that many aerospace firms are forced to deal with, and a problem that companies such as Boeing take a keen interest in. Suppliers to Boeing and other aerospace OEMs are tasked with proving that their derived models have not significantly changed from the original sent them by the customer, via Boeing validation document D6-51991.

Section 7 of aerospace spec AS9100 is concerned with verification and validation procedures, many of which are answerable with validation tools such as MagicCheck.

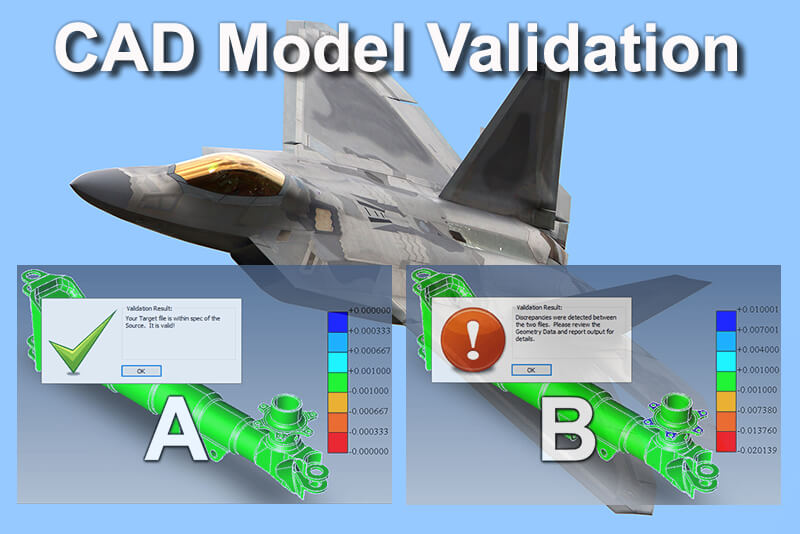

CAD comparison software can authenticate two parts, comparing the original master model and the derived check model to determine how close they are in hundredths, thousandths, or ten-thousandths of an inch or millimeter. The screenshot at above, right shows an example of a passed validation analysis, and a failed validation analysis.

See an example of how CAD model validation works in the video below.

Special CAD Model Validation Offer

In the past year we’ve all been through some challenges. TransMagic wants to assist aerospace firms who need to comply with Boeing Spec D6 51991 and other standards to ensure that derived models and the CAD authority model are within tolerance.

TransMagic MagicCheck provides CAD Model Validation compliance analysis, as well as revision analysis and point-to-part analysis, for checking measured prototypes against the CAD model.

Take TransMagic MagicCheck for a spin for 90 days, on us.

To talk to a customer service rep: Please call 1-303-460-1406 or email Sales@TransMagic.com.